Remote Control: 3D printing simulation on Dome surface

[Video] Remote Control: 3D printing simulation on Dome surface

[Video] Remote Control: 3D printing simulation on saddle surface

[Video] Conformal 3D Printing Using YASKAWA GP12

"3D Printing Conformal Antenna"

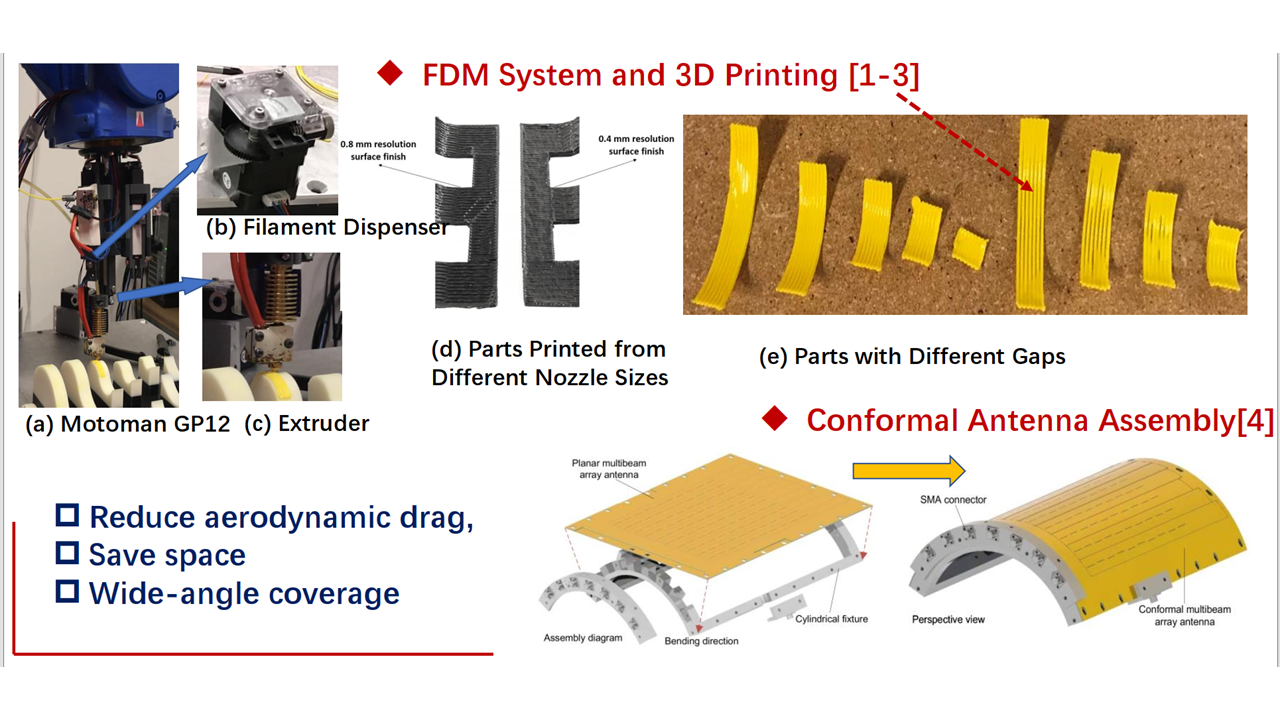

· Worked on Additive Manufacturing 3D Printing of Conformal Antenna

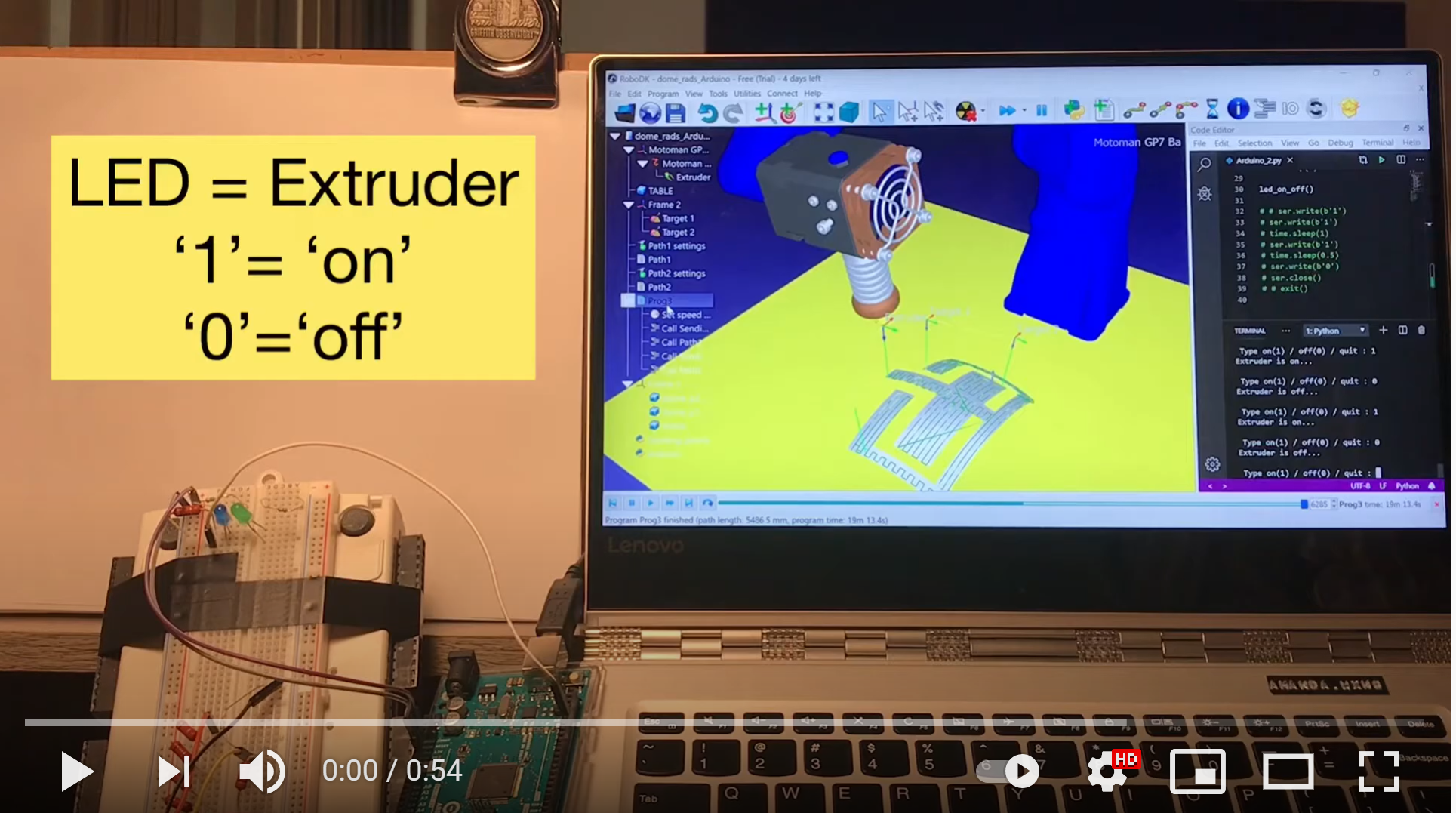

· Designed an Arduino – Python UDP communication system for manually and remotely control for robot 3D printing with linear control and robotic path planning algorithm involved

- Catalogue: Directed Research (Advisor: Prof. Satyandra K. Gupta)

- Project Director: Prof. Satyandra K. Gupta, Yeo Jung Yoon

- Summary: This report presents the idea of Multuchip Conformal Antenna 3D printing using Additive Manufacturing Method. Firstly, By generating separate parts path in the 3D printing, The Multichip Conformal 3D printing using FDM with certain nozzle size(0.8) has the ability to print relatively small size of conformal antenna with more details. In addition, the idea of Multi-layer conformal printing is introduced to improve the antenna model performances. Secondly, the UDP between extruder and robot is designed to control the extruder on during printing parts and off while moving between parts, in which case, solve the problem of filament redundant deposition among unwanted location. Both the Automatically and Manually Extruder control are introduced in UDP control. In addition, the Multichip 3D Printing among four surfaces with different radius of curvatures(flat, cylinder, dome, saddle) are implemented by RoboDK API simulation, which paves the foundation of further research. Key Words: Multichip 3D printing; Conformal Antenna; Additive Manufacture; UDP between Python and Arduino

-

Results:

In this report, the several conclusions are reached:

1) The path planning for Multichip Conformal Antenna 3D printing using Additive Manufacturing Method are plausible to implement. By tweaking the model and MATLAB codes, the problems such as path overlapping and brim wrapping could be well fixed.

2) The idea of Multi-layer Conformal Printing in Multichip is introduced to improve the local strength and local joint position planning.

3) The UDP between extruder and robot is designed to control the extruder on during printing parts and off while moving between parts. Both the Automatically and Manually Extruder control are introduced in UDP control. The use of Bluetooth and infrared remoter can provide different idea for the Extruder Remote Control.

4) The Multichip 3D Printing among four distinctly different surfaces are Simulated by RoboDK API along with Python UDP with Arduino.

To be continued: Conductive Printing Material used for Conformal 3D printing.